2026 Top Slitter Cutter Machine Features and Benefits Explained?

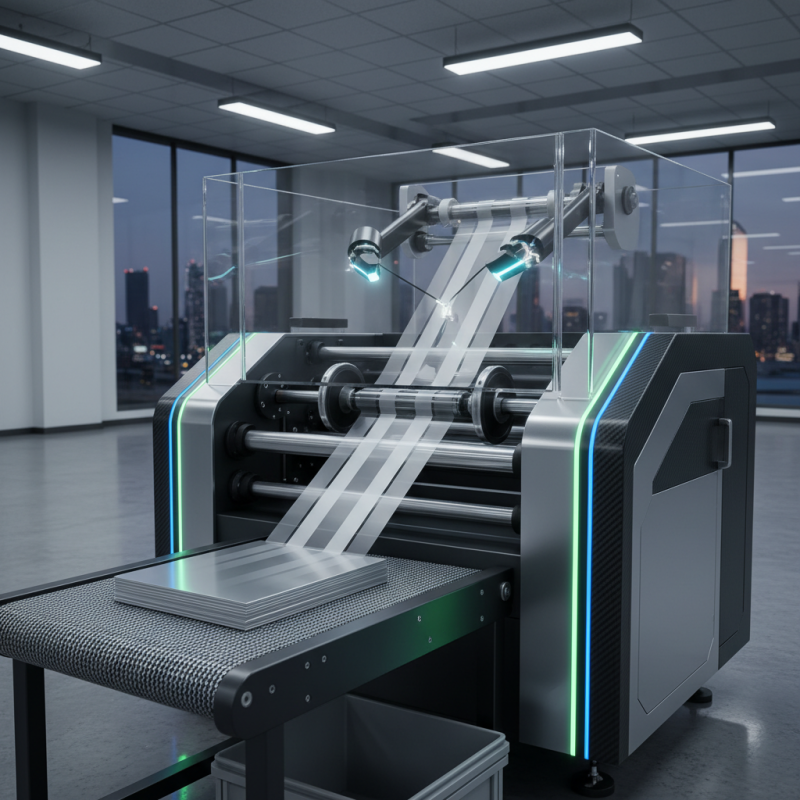

In the fast-paced world of manufacturing, the Slitter Cutter Machine stands out for its efficiency and precision. Designed to simplify the cutting process, this machine is a game changer in various industries. The latest models for 2026 incorporate advanced technology and innovative features that can significantly enhance productivity.

With impressive cutting capabilities, the Slitter Cutter Machine caters to diverse materials like paper, plastic, and metal. Users can expect more from their machines, yet some operators may still face challenges in mastering these advanced technologies. The blend of speed and accuracy offers a unique opportunity, but adapting to new features requires careful consideration.

Investing in a modern Slitter Cutter Machine is more than just a financial decision. It involves rethinking workflows and adapting to new methods. While the benefits are substantial, potential users should reflect on their specific needs and readiness for technological upgrades. Embracing this machine could lead to substantial growth, but it demands commitment and understanding.

Overview of Slitter Cutter Machines in 2026

Slitter cutter machines have evolved significantly in 2026, showcasing advanced features that cater to various industries. These machines are now designed for precision cutting, ensuring uniformity in each product slice. High-speed operations have become a core feature, drastically improving productivity. Efficiency is at the forefront of design, reducing waste and saving costs for manufacturers.

However, even with these advancements, there are areas to reflect on. For instance, the initial setup of slitter cutter machines can sometimes be complex. Training operators remains essential to fully leverage the machine's capabilities. Maintenance procedures can also be intricate, requiring careful adherence to guidelines. As manufacturers strive for innovation, addressing these challenges is vital to maximize operational effectiveness.

The versatility of slitter cutter machines is noteworthy. They can handle various materials, from paper to plastics. This adaptability opens doors for businesses to diversify their production lines. Nonetheless, selecting the right machine for specific needs can be daunting. It is crucial to balance features with practical application to avoid unnecessary investments. Overall, the landscape of slitter cutter machines in 2026 presents both opportunities and challenges for businesses aiming for technological advancement.

Key Features of Advanced Slitter Cutter Technology

Advanced slitter cutter technology offers several key features that enhance efficiency and precision in manufacturing processes. One significant aspect is the ability to handle various materials, including plastic films, paper, and metal. According to industry reports, advanced slitter cutters can improve throughput by up to 30%. This flexibility allows companies to diversify their product ranges without major equipment changes.

Another critical feature is automation. Modern slitter cutters come equipped with smart technology that enables real-time monitoring. This can lead to a reduction in waste material by as much as 20%. The integration of sensors facilitates better alignment and tension control. However, companies often face challenges when integrating these technologies into existing systems. The learning curve can slow down production initially.

Moreover, the lifespan of cutting blades has improved significantly with new materials and coatings. Reports indicate that blades can last up to 50% longer than older models. Yet, this advance can lead to complacency in maintenance practices. Neglecting consistent upkeep may undermine the potential benefits, leading to unexpected breakdowns. Balancing innovation and traditional practices remains a critical concern in the industry, requiring ongoing attention and adaptation.

Benefits of Enhanced Efficiency in Slitting Operations

Efficiency is a key concern in slitting operations. Improved efficiency means reduced waste and higher throughput. According to industry data, enhancing slitting line efficiency by just 10% can lead to significant cost savings. This is crucial for manufacturers looking to maximize margins in a competitive market.

The latest slitter cutter machines are designed to streamline workflows. Features like advanced tension control ensure consistent material feed. This reduces the risk of defects and improves overall product quality. Reports indicate that machines with automated adjustments can boost production speed by up to 25%. However, integrating these machines requires a thoughtful approach. Operators must be trained properly to harness their full potential.

While new technology offers numerous benefits, challenges remain. Some operators report difficulties in adapting to advanced software controls. Technical glitches can disrupt operations, leading to downtime. Therefore, a balance between technology and operator skills is essential. Investing in training programs can bridge this gap and foster a more efficient work environment. Enhanced efficiency is not just about machines; it's also about human capability.

Impact of Slitter Cutter Innovations on Various Industries

In recent years, slitter cutter innovations have significantly impacted various industries. These machines have evolved to enhance precision and efficiency. Industries like packaging, textiles, and printing have seen remarkable improvements. The ability to cut materials with finer tolerances leads to reduced waste, which is crucial for eco-friendly practices.

Moreover, advancements in technology provide better control over the cutting process. Users can now adjust settings quickly, adapting to different materials with ease. However, while these innovations are impressive, integrating new machinery poses challenges. Staff training becomes essential for smooth operation. Sometimes, implementation delays occur due to a lack of expertise.

Another aspect to consider is the machine's maintenance. New features often require specialized care. Companies must be proactive in scheduling regular check-ups. This additional responsibility might conflict with other operational needs. Still, the long-term benefits of these innovations remain compelling for many sectors. Balancing innovation with practical challenges is key for any industry looking to thrive in a competitive landscape.

Impact of Slitter Cutter Innovations on Various Industries

This chart illustrates the impact of slitter cutter innovations on various industries based on efficiency improvements and cost savings over the years. The data represents the percentage improvement in productivity and cost reduction attributed to advancements in slitter cutter technology.

Future Trends in Slitter Cutter Machine Development

The development of slitter cutter machines is evolving rapidly. In 2026, we can expect cutting-edge features that focus on efficiency and precision. The integration of smart technology will streamline operations. Automated adjustments may replace manual settings, enhancing accuracy. Yet, this shift could create a learning curve for operators. They must adapt to new interfaces and control systems.

Sustainability trends will shape machine design. Eco-friendly materials may replace traditional components. Reduced energy consumption will be a priority, but it raises questions about cost-effectiveness. Companies often grapple with balancing sustainability and profitability. Enhanced safety features will likely be a focus too, but implementation can be inconsistent. Operators must ensure compliance with safety standards to prevent accidents.

As we look ahead, the role of data analytics will grow. Smart machines will collect and analyze performance data in real time. This can lead to improved production rates and reduced downtime. Yet, reliance on data could lead to overconfidence, risking human oversight. Balancing technology and human insight remains a crucial challenge in this evolving landscape.

2026 Top Slitter Cutter Machine Features and Benefits Explained

| Feature | Description | Benefits | Future Trend |

|---|---|---|---|

| High Precision Cutting | Utilizes advanced sensors and controls for accurate cutting. | Reduces material waste and improves product quality. | Continued integration of AI for enhanced precision. |

| User-Friendly Interface | Intuitive touchscreen controls for ease of use. | Simplifies operation, reducing training time for staff. | Trend towards customizable interfaces tailored to user needs. |

| Modular Design | Easily adjustable components for different materials. | Increased versatility allows for diverse applications. | Growing demand for adaptable machinery in production lines. |

| Energy Efficiency | Optimized energy consumption through advanced motors. | Lower operational costs and improved sustainability. | Emerging focus on green technology in industrial equipment. |

| Data Analytics Integration | Real-time monitoring and analysis of cutting performance. | Enables predictive maintenance and enhances operational efficiency. | Continuous evolution towards IoT and smarter machines. |