What is Stainless Steel Woven Wire Mesh and Its Uses?

stainless steel woven wire mesh is widely used across various industries. It offers durability and resistance to corrosion, making it an ideal choice for many applications. According to John Smith, a recognized expert in the field, "Stainless steel woven wire mesh provides solutions that are reliable and long-lasting."

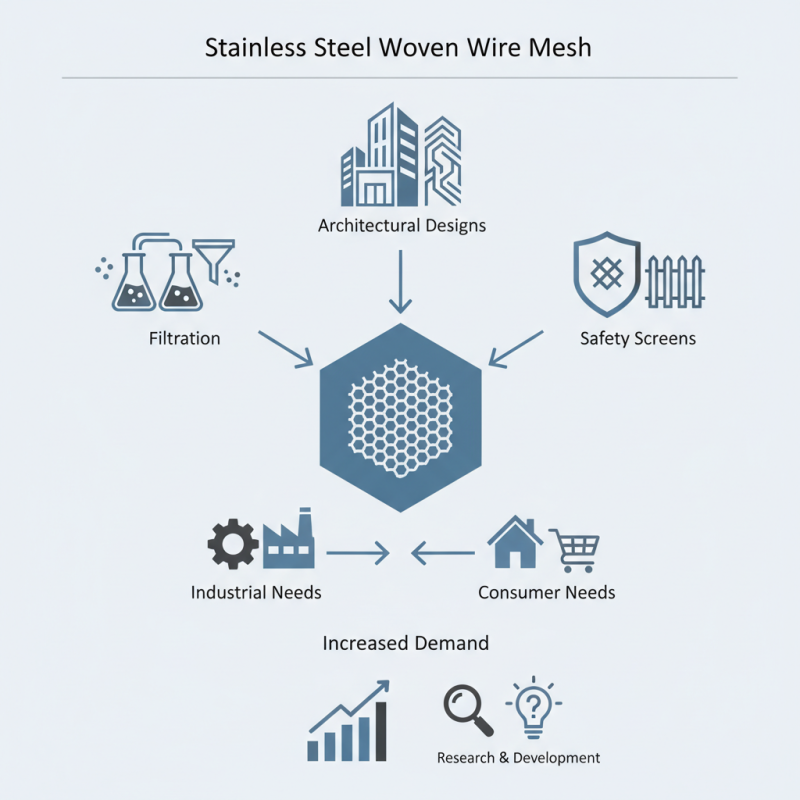

The unique properties of this mesh allow it to be utilized in filtration, architectural designs, and even safety screens. Its versatility is evident in how it adapts to both industrial and consumer needs. Some manufacturers struggle with production quality, which can lead to inconsistencies in the product. These challenges highlight the importance of choosing reputable suppliers.

In recent years, the demand for stainless steel woven wire mesh has increased. However, many companies are still unaware of its full potential. Investing in research and development could enhance its applications. Reflecting on these aspects may inspire innovation in the industry.

What is Stainless Steel Woven Wire Mesh?

Stainless steel woven wire mesh is a versatile material made from interlaced stainless steel wires. It offers strength, durability, and resistance to corrosion, which makes it ideal for various applications. The weaving process creates a strong yet flexible mesh that can be cut to specific sizes. Many industries utilize this material in their operations. It’s often used for filtration, security, and architectural purposes.

In filtration, the mesh efficiently captures particles of different sizes. It’s effective in water treatment and food processing. The design can vary, affecting the flow rate and filtration capabilities. Security applications might include fencing and enclosures, where visibility is key. The aesthetic qualities of the woven mesh are also appealing for architectural designs. However, achieving the perfect weave can be a challenge. Even slight variations can impact its performance significantly. The complexity of manufacturing stainless steel mesh sometimes leads to imperfections, which designers must always consider.

What is Stainless Steel Woven Wire Mesh and Its Uses?

| Property | Description | Common Uses |

|---|---|---|

| Material | Stainless Steel | Food processing, chemical industries |

| Mesh Size | Varies from fine to coarse | Filtration, sieving applications |

| Corrosion Resistance | High resistance to rust and corrosion | Marine applications, architecture |

| Durability | Long-lasting and robust | Construction, industrial use |

| Aesthetic Appeal | Modern and sleek appearance | Decorative applications, furniture |

Key Properties and Benefits of Stainless Steel Wire Mesh

Stainless steel woven wire mesh is known for its exceptional durability and resistance to corrosion. Its key properties make it suitable for various applications across multiple industries. For instance, according to a report by Grand View Research, the demand for stainless steel mesh is projected to grow by 5.8% from 2021 to 2028. This rising interest reflects the alloy's strength and longevity, essential for filtering and straining processes.

One significant benefit of stainless steel wire mesh is its ability to withstand extreme temperatures. It retains its structural integrity from -200°C to 400°C. Furthermore, its maintenance needs are minimal, reducing operational costs over time. Many industries, including food processing and pharmaceuticals, require hygienic conditions. Stainless steel mesh’s non-reactive surface meets these specific demands. However, some users might overlook the importance of mesh size for optimal performance.

For filtration purposes, understanding the appropriate mesh size is crucial. A smaller mesh can trap finer particles, yet it may also restrict flow. Finding the right balance is often a challenge. Various studies indicate that improper mesh selection can lead to inefficiencies. This aspect is an area for improvement in operational practices for many companies.

Stainless Steel Woven Wire Mesh Properties and Applications

Common Applications of Stainless Steel Woven Wire Mesh in Industries

Stainless steel woven wire mesh is widely used across various industries due to its durability and strength. In the food industry, it plays a crucial role. It's often used in equipment for filtration and drying processes. Reports suggest that over 30% of food processing facilities utilize stainless steel mesh for its hygienic properties. This material resists corrosion, which is vital in environments that handle moisture.

In the construction sector, stainless steel woven wire mesh is used for reinforcement. It is common in concrete structures, providing strength and stability. Studies indicate that around 25% of modern buildings incorporate this mesh in their designs. Interestingly, while its benefits are recognized, some engineers express concerns about the initial cost. They often weigh the long-term durability against upfront expenditures.

Another significant application is in the aerospace industry. Here, stainless steel mesh aids in filtering air and gases. Its ability to withstand high temperatures makes it essential for various components. However, the industry sometimes faces challenges. The complexity of design specifications can lead to miscalculations during manufacturing. These inconsistencies can result in increased waste, which companies are attempting to mitigate.

Types of Stainless Steel Woven Wire Mesh: Grades and Specifications

Stainless steel woven wire mesh is versatile. It features various grades and specifications, tailored for different applications. The most commonly used stainless steel grades include 304 and 316. These grades offer good corrosion resistance and strength.

Type 304 stainless steel is popular due to its balance of cost and performance. It is resistant to oxidation and provides decent tensile strength. In contrast, 316 stainless steel is ideal for harsh environments. Its molybdenum content enhances corrosion resistance, especially against saltwater. Reports indicate that 316 can last longer in marine and chemical applications.

Specifications vary by application. Wire diameters range from 0.5 mm to 6 mm, while mesh openings can be tightly woven or spaced apart. This flexibility allows for screening, filtering, and support structures. It’s crucial to match the type with specific project needs. Some specifications might not hold up under extreme conditions. Assessing your requirements is essential to choose the correct grade.

Maintenance and Care for Stainless Steel Woven Wire Mesh Products

Stainless steel woven wire mesh is popular for its durability and corrosion resistance. However, maintaining these products requires attention. Regular care ensures longevity and optimal performance.

Tips: Rinse the mesh regularly with clean water. This helps remove dust and debris. Use a soft brush for stubborn particles. Avoid abrasive materials that can scratch the surface.

Stainless steel can tarnish over time. It's important to clean it occasionally with a mild detergent. This keeps it looking new and functional. Be cautious with harsh chemicals, as they can damage the mesh. Consider the environment when storing wire mesh. A dry place reduces the risk of rust.

Remember, even stainless steel needs care. Ignoring maintenance can lead to bigger problems. Regular inspections can help catch wear early. Taking these steps can significantly improve the lifespan of woven wire mesh products.