Essential Tips for Choosing Sandblast Rubber Hose?

When selecting the right Sandblast rubber hose, the choices can seem overwhelming. Industry expert John Smith, a veteran in the abrasive blasting field, emphasizes, “Quality hoses make all the difference in performance.” As operators face various tasks, each application demands specific attributes from a Sandblast rubber hose.

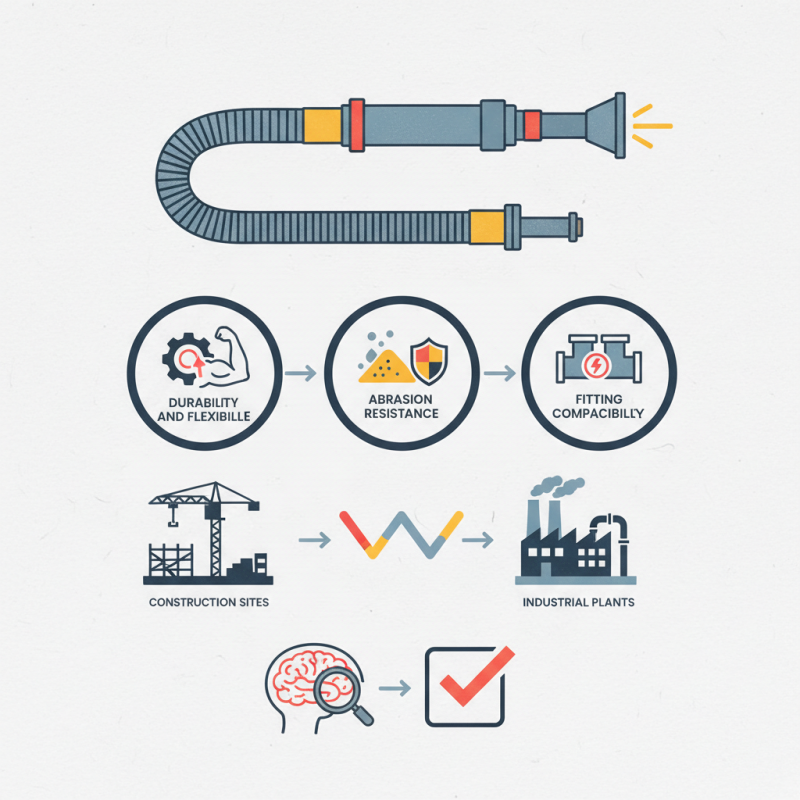

Consider the varying environments where these hoses are used. From construction sites to industrial plants, the durability and flexibility of the hose are critical. Attention to details like the hose’s abrasion resistance can prevent costly downtime.

However, not all hoses are created equal. Potential buyers may overlook the importance of fitting compatibility. A poor connection can lead to hazardous leaks or inefficiencies. Choosing a Sandblast rubber hose requires careful consideration and an understanding of both the material and the intended use. Reflecting on these factors is essential for success in any abrasive blasting operation.

Understanding Sandblast Rubber Hose Specifications

When selecting a sandblast rubber hose, it’s crucial to understand its specifications. These hoses are designed for high-pressure situations and abrasive materials. You must check the working pressure rating. It determines the maximum pressure the hose can handle. A hose with a low rating may fail under pressure. Look for hoses that can withstand rough usage.

Another important specification is the hose diameter. Larger diameters allow for increased flow rates, which can enhance efficiency. However, a hose that is too large may be cumbersome and difficult to manage. Consider the weight of the hose, too. A lightweight hose is easier to handle but may sacrifice durability.

In addition, the material quality matters greatly. Look for a rubber that resists wear and tear. Ensure that the hose has good flexibility while remaining strong. Testing the hose under various conditions can reveal shortcomings. Sometimes, a hose appears perfect but may not perform well in real-life scenarios. Always be ready to make adjustments and learn from the purchase experience.

Evaluating Durability and Flexibility of Rubber Hose Materials

When selecting sandblast rubber hoses, it’s crucial to evaluate the durability and flexibility of the materials used. High-quality rubber is designed to withstand severe abrasion and harsh environments. According to a report by the Rubber Manufacturers Association, hoses can experience a lifespan reduction of 20-30% when exposed to extreme conditions. This highlights the importance of material selection in prolonging hose life.

Flexibility is also essential. A rubber hose that retains flexibility will reduce the risk of kinks and wear. Studies show that hoses with a shore hardness of 60A to 70A maintain optimal flexibility without sacrificing strength. Meanwhile, softer materials might tear easily, while harder ones might crack. It's a delicate balance. It’s best to test hoses in real work conditions before committing to them long-term.

Moreover, consider the environmental factors. Factors like heat, chemicals, and pressure can influence a hose's performance. Research indicates that 40% of hose failures occur due to improper material selection or environmental neglect. This suggests that proper testing and evaluation should not be overlooked in the decision-making process. It’s a complex equation to solve. Finding the right rubber hose requires careful thinking and consideration.

Essential Tips for Choosing Sandblast Rubber Hose

| Property | Description | Importance |

|---|---|---|

| Material Composition | Natural rubber, synthetic rubber, and blends | Affects durability and resistance to abrasives |

| Hardness | Measured in Shore A durometer | Higher hardness may offer better wear resistance |

| Temperature Resistance | Ability to withstand extreme temperatures | Prevents hose failure in extreme conditions |

| Flexibility | Ease of manipulation and bending | Essential for handling and installation in tight spaces |

| Pressure Rating | Maximum pressure the hose can withstand | Ensures safety and reliability during operation |

| Abrasion Resistance | Ability to resist wear from abrasive materials | Critical for applications involving sandblasting |

| Compatibility | Compatibility with various blasting medias | Ensures longevity and effectiveness of the hose |

| End Fittings | Type of connections on each end of the hose | Must be durable and fit securely with equipment |

Determining Proper Hose Diameter and Length for Sandblasting

When selecting a sandblast rubber hose, proper diameter and length are crucial. The diameter impacts airflow and material velocity. Inadequate diameter can cause clogging and inconsistent performance. Industry reports suggest that hoses with a diameter between ½ inch and 1 inch are ideal for most applications, allowing for optimal material flow.

Length is also vital. Longer hoses may reduce pressure and affect performance efficiency. A report indicates that a hose length exceeding 25 feet could lead to a 20% reduction in performance. However, if the hose is too short, it may limit the operator's movement, creating safety hazards. Operators should consider their work area and intended use when determining hose length.

It is essential to balance diameter and length. A too-thin or too-short hose can lead to poor results and increased wear. Many professionals overlook these aspects, leading to operational inefficiencies. Regular assessments and adjustments based on actual usage can significantly enhance performance and safety in sandblasting applications.

Assessing Compatibility with Various Abrasive Materials

Choosing the right sandblast rubber hose is crucial for achieving optimal performance. Compatibility with various abrasive materials is a key factor in this decision. Different abrasives have unique characteristics and behaviors, which can affect the lifespan of the hose. For example, materials like silica can be very abrasive, causing excessive wear to subpar hoses. On the other hand, less abrasive materials may not pose as much of a risk.

It's essential to assess the hose's resistance to wear and tear. Look for hoses with reinforced inner linings. These provide better durability against harsh materials. However, not all hoses are created equal. Some may excel with certain abrasives but falter with others. This inconsistency can lead to unexpected failures during usage. Therefore, testing the hose with the specific abrasive you plan to use is recommended.

Consider the hose's flexibility and weight as well. A heavier hose can be cumbersome and difficult to maneuver, especially in tight spaces. Assessing the compatibility with the specific abrasive and the working environment is crucial. Each project can have different requirements, and what worked before may not work now. Don't overlook these details.

Exploring Safety Features and Maintenance Tips for Sandblast Hoses

When selecting a sandblast rubber hose, safety should be a primary concern. It's crucial to ensure that the hose you choose can withstand high pressure. Look for hoses that have reinforced walls. This feature is essential, as it prevents bursting during intense operations. Regular checks for wear and tear are vital. A slight crack can lead to dangerous leaks. Inspect both the exterior and the interior of the hose frequently.

Maintenance plays a significant role in extending the life of your sandblast hose. Always clean the hose after use to remove any abrasive materials. Storing the hose properly is another key point. Avoid crushing or kinking it, as this can damage the structure. Consider placing the hose on a reel to keep it organized. During usage, observe the temperature of the hose. If it becomes excessively hot, take a break to let it cool down. This simple act prevents degradation and promotes safety.